Customized samples, deep processing (stamping, bending, etc.), rough processing (kaiping, slitting, etc.), other processing services

Product parameters

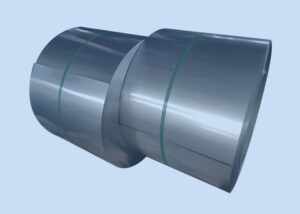

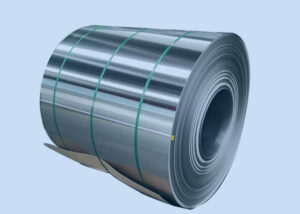

| Product Name | carbon steel coil |

| Wall Thickness | 0.17mm-1.7mm |

| Width | 600mm-1250mm |

| Tolerance | Thickness:±0.03mm, Width: ±50mm, Length: ±50mm |

| Material | Q345B,Q345C,Q345D,Q345E,Q390,Q390B,Q390C, |

| Q390D,Q390E,Q420,Q420B,Q420C,Q420DQ420E, | |

| Q460,Q460D,Q500C,Q500D,Q500E,Q550C,Q550D, | |

| Q550E,Q620C,Q620D,Q620E,Q690A,Q690B,Q690C, | |

| Q690D,Q690E,Q690D,Q690C,Q890C,Q890D | |

| 16Mo3,16MnL,16MnR ,16Mng,16MnDR | |

| Technique | Hot/cold Rolled |

| Surface treatment | Top paint: PVDF, HDP, SMP, PE, PU |

| Prime paint: polyurethane, epoxy, PE | |

| Back paint: epoxy, modified polyester | |

| Standard | ASTM, JIS, EN |

| Certificate | ISO, CE |

| Payment terms | 30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100% Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days, O/A |

| Delivery times | Delivered within 30 days after the receipt of deposit |

| Package | tied up with steel strips and wrapped with water proof paper |

| Loading port | Xingang, China |

| Application | Widely used in roofing sheet, window-shades, car ceiling, the shell of the car, air conditioner, outer shell of water machine, steel structure etc |

| Advantages | 1. Reasonable price with excellent quality |

| 2. Abundant stock and prompt delivery | |

| 3. Rich supply and export experience, sincere service |

Product description

Steel coil, also known as coil steel. The steel is hot-pressed and cold-pressed into rolls. In order to facilitate storage and transportation, and facilitate various processing (such as processing into steel plates, steel strips, etc.), the formed coils are mainly hot-rolled coils and cold-rolled coils. Hot rolled coil is the processed product before the recrystallization of the steel billet. Cold rolled coil is the subsequent processing of hot rolled coil. The general weight of the steel coil is about 15-30T

Using slab (mainly continuous casting billet) as raw material, after heating, it is made into strip steel by rough rolling mill and finishing mill. The hot steel strip coming out of the last rolling mill of finishing rolling is cooled to the set temperature by laminar flow, and is coiled into steel coils by the coiler. The cooled steel coil, according to the different needs of users, is processed by different finishing lines to become steel plate, flat coil and slit steel strip products.

Because steel coil products have high strength, good toughness, and a wide variety of steel specifications, they are also widely used. They are widely used from general engineering structures to the manufacture of automobiles, bridges, ships, boilers and pressure vessels. Different uses have different requirements on the material properties, surface quality, size, and shape accuracy of steel plates. Therefore, it is necessary to understand the varieties, materials, characteristics and uses of steel coil products in order to achieve economical and rational use.

PROGRESUL

PROGRESUL