| Product Name | 6061 Aluminum |

| Alloy | 6061 aluminum are alloyed with magnesium and silicon, are easy to machine and can be precipitation hardened that not to the high strength that 2000 and 7000 series can reach. |

| Temper | H12,H14,H16,H18,H19 etc. |

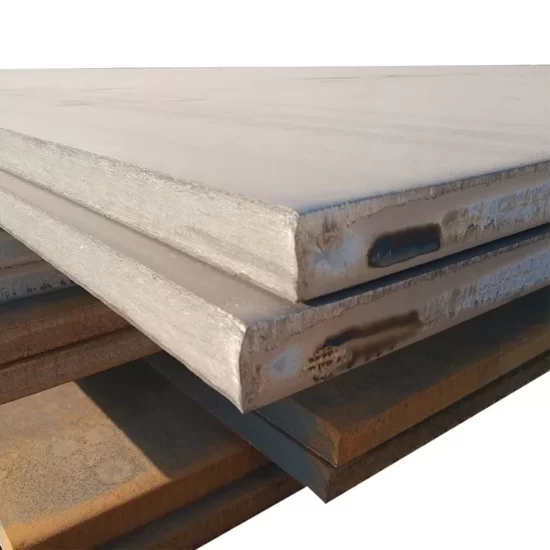

| Thickness | 0.1mm to 10mm |

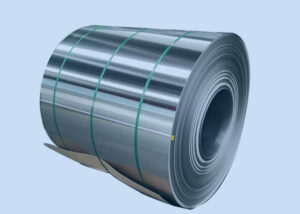

| Width | For coil: 600mm ~ 2000mm, or as customize |

| For sheet: 20mm ~ 2200mm, or as customize | |

| Weight/Coil | As the customer’s request |

| MOQ | 3 ton |

| Delivery time | Aound 30 days |

| Payment terms | T/T L/C |

| Container | 20ft: 5898mm(L)*2352mm(W)*2393mm(H) Loading 18-25 tons 40ft:12032mm(L)*2352mm(W)*2393mm(H) Loading 25-27 tons |

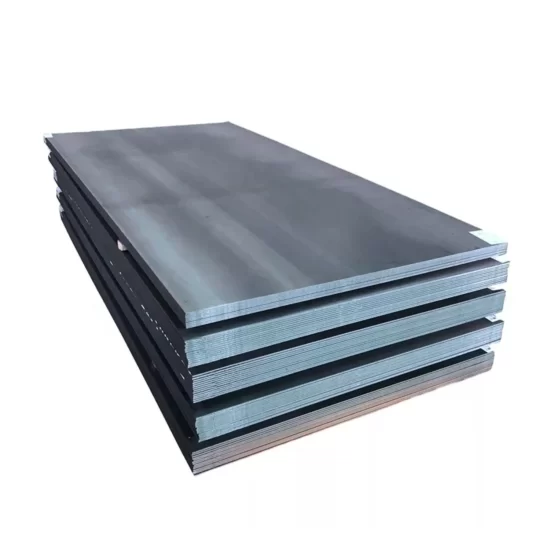

| Packing | 3 layers of packing. Inside is craft paper, Middle is water plastic film and outside GI steel sheet to be covered by steel strips |

Chemical Composition

| Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | V | Zn | Ti | Residuals | |

| 6061 | 0.3-0.6 | 0.1-0.3 | ≤0.10 | ≤0.10 | 0.8-1.2 | 0.04-0.35 | / | ≤0.15 | ≤0.10 | ≤0.15 |

Mechanical Properties

| Mechanical Properties | |

| Property | Value |

| Tensile Strength | 130 to 410 MPa |

| Yield Strength | 76 to 370 MPa |

| Elongation | 3.4 to 20% |

| Shear Strength | 84 to 210 MPa |

Tempers

- 6061-O Aluminum

- 6061-T1 Aluminum

- 6061-T4 Aluminum

- 6061-T42 Aluminum

- 6061-T451 Aluminum

- 6061-T4510 Aluminum

- 6061-T4511 Aluminum

- 6061-T51 Aluminum

- 6061-T6 Aluminum

- 6061-T62 Aluminum

- 6061-T651 Aluminum

- 6061-T6510 Aluminum

- 6061-T6511 Aluminum

- 6061-T652 Aluminum

- 6061-T89Aluminum

- 6061-T94 Aluminum

Other Designations

| AMS 4117 | ASTM B247 | ASTM B429 | DIN 3.3211 | MIL G-18014 | QQ A-200/8 |

| ASTM B209 | ASTM B307 | ASTM B483 | MIL A-12545 | MIL G-18015 | QQ A-225/8 |

| ASTM B210 | ASTM B313 | ASTM B547 | MIL A-22771 | MIL P-25995 | QQ A-250/11 |

| ASTM B211 | ASTM B316 | ASTM B548 | MIL F-17132A | MIL T-7081 | QQ A-367 |

| ASTM B221 | ASTM B345 | ASTM B632 | MIL F-18280 | MIL W-23351 | QQ A-430 |

| ASTM B234 | ASTM B361 | ASTM F467 | MIL F-39000 | MIL W-85 | QQ WW-T-700/6 |

| ASTM B241 | ASTM B404 | ASTM F468 | MIL F-3922 | QQ A-200/16 | SAE J454 |

Fabrication and Heat Treatment

Machinability

Aluminium / Aluminum 6061 alloy has good machinability in harder T 4 and T6 tempers. It can be machined in an annealed temper.

Forming

Aluminium / Aluminum 6061 alloy can be easily formed and worked in the annealed condition. The standard methods are used to perform bending, stamping, deep drawing, and spinning operations.

Welding

Aluminium / Aluminum 6061 alloy has excellent weldability. Thinner sections can be welded using the gas tungsten arc welding technique.

Forging

Aluminium / Aluminum 6061 alloy is forged at 233 to 483°C (750 to 900°F).

Application

- Truck and marine components

- Furniture

- General structural and high-pressure applications

- Pipelines

- Heavy-duty structures

- Railroad cars

- Tank Fittings

Process Flow

FAQ

1. Q:Are you a manufacturer or trading company?

A: We are a manufacturer, can do OEM and ODM.

2. Q: Can i get some samples? What product information do i need to provide?

A: Yes, we have small samples, like A4 size. You need to provide the grade (ALLOY NUMBER) and temper, thickness, width,length and the quantity.

3. Q: How does your factory do regarding quality control?

A: Quality is priority. Our factory has gained SGS authentication. We guarantee the goods out form our factory 100% qualified. And each process, we have very strict operation and arrange 2 technicians to inspect. After the products are finished, we will make the last test to pick up the unqualified products.

4. Q:What is your payment?

A: Generally we accept 30% T/T as deposit and 70% against with B/L copy

Packing & Shipping

QIDAMT

QIDAMT