| Nome del prodotto | 201/304/316/316L/310S stainless steel angle bar |

| Standard | ASTM A240/240M , Aisi, GB1220 , LUI, DIN17440, EN |

| Origine | Goldpro |

| Surface finished | 2B,BA,2BA,No.1,8k Mirror, HL and No.4 hairline,Linen,brushed,color coating,embossing, etched |

| Technique | Cold Drawn Hot Rolled Forged |

| Edge | Mill edge , Slit edge |

| Package | 1)3 ton Packed in one nylon bag, fixing by the packing strap,with two mark of product details2)Nylon bag packing, export special wooden box packing,fixing by steel strap,with two mark of products details . |

| Productivity | 5000 ton every month |

| Payment | 1) 30% by T/T as deposit, 70% by T/T before shipping |

| 2) 30% by T/T as deposit, 100% by L/C AT SIGHT ON B/L | |

| 3) 100% by L/C AT SIGHT ON B/L | |

| Tempi di consegna | 1) Stock size: Within 3days after deposit |

| 2) Customize Size: Within 7days after deposit | |

| 3) OEM Product: 15-30 days after deposit | |

| Porto di carico | Shanghai port |

| MOQ | 1 MT |

| Applicazione | 1) Automotive Trim and Molding |

| 2) Builders Hardware, Fasteners ,and Furnace Parts | |

| 3) Interior Architectural Trim and Paneling | |

| 4) Kitchen Trim and Equipment | |

| 5)Zippers, Vaults, and Tubing | |

| 6)Tobacco Machinery, Television Cones, and Storage Vessels |

The tolerance of stainless steel size

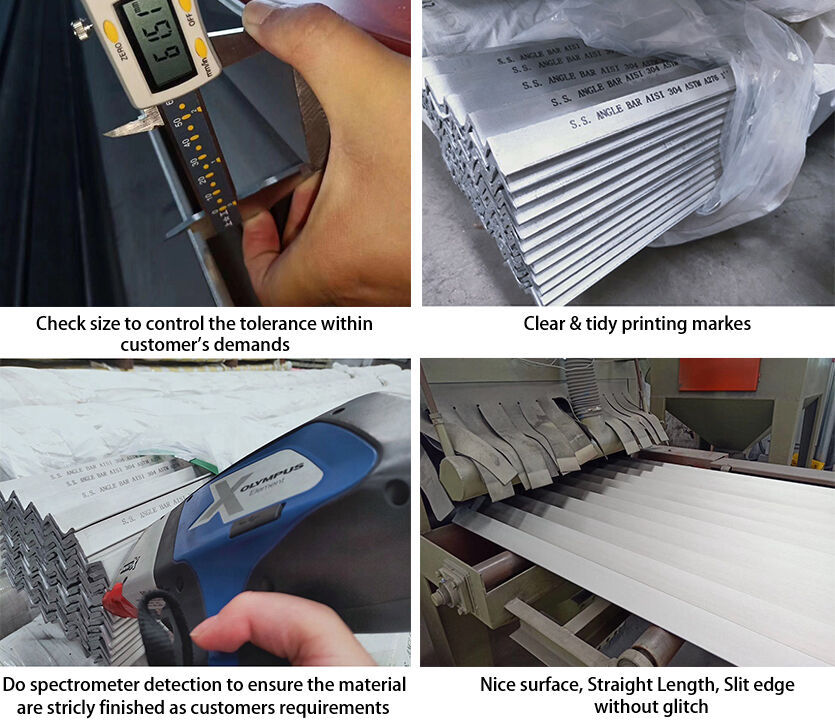

Quality detection

In our company, the prime product can only be packaged and shipped after passed four inspections. We can guarantee that the products from our factory are all prime quality and with One-year after-sales service.

Our processing service

Our 201/304/316/316L/310S stainless steel angle bar service is the basis of cooperation, and the recognition of customers determines the stability of our long-term strategic partnership. We can laser cutting any shape and any size on stainless steel angle bar as your requirements. We also can polishing the surface of 304/316 ss steel angle bar,such as 8k mirror polishing, sandblasted surface and Brushed hairline surface.

Why choose our processing service?

1) Our processing equipment is the best in the country

2) Our engineers are the most experienced

3) Our packaging staff are the most professional

4) Our sales staff are the most patient

Production equipment

At present, we can provide cutting, slitting, laser cutting sheets, laser cutting tubes and profiles, sawing cutting rods and tubes, flessione, welding, stampaggio, CNC machining, the smallest laser drilling diameter can be 0.15mm in diameter, The largest machinable size is 1020mm diameter, the maximum error of the laser is only 0.05mm, the maximum tolerance of the sawing machine is less than 0.15mm, and the length error is 0.05-0.1mm. Believe that our profession will be able to get your greatest recognition and support.

| Production equipment | No. | years | Disponibile |

| Precision ss strip proction | 3 | 6/6/5 | yes |

| Cold rolled cutting+slitting machine | 2 | 8/8 | yes |

| Hot rolled cutting+slitting machine | 2 | 6/6 | yes |

| Bending machine | 2 | 7/6 | yes |

| Welding machine | 2 | 7/6 | yes |

| Laser cutting on ss plate | 1 | 5 | yes |

| Laser cutting on ss pipe and profile | 1 | 5 | yes |

| Polishing on thick ss sheet | 1 | 3 | yes |

| Hairline machine | 2 | 7/5 | yes |

| Coil 8k mirror procssing machine | 2 | 3/3 | yes |

| sheet 8k mirror procssing machine | 2 | 6/5 | yes |

| CNC machining processing | 6 | 8/7/6/6/5/5 | yes |

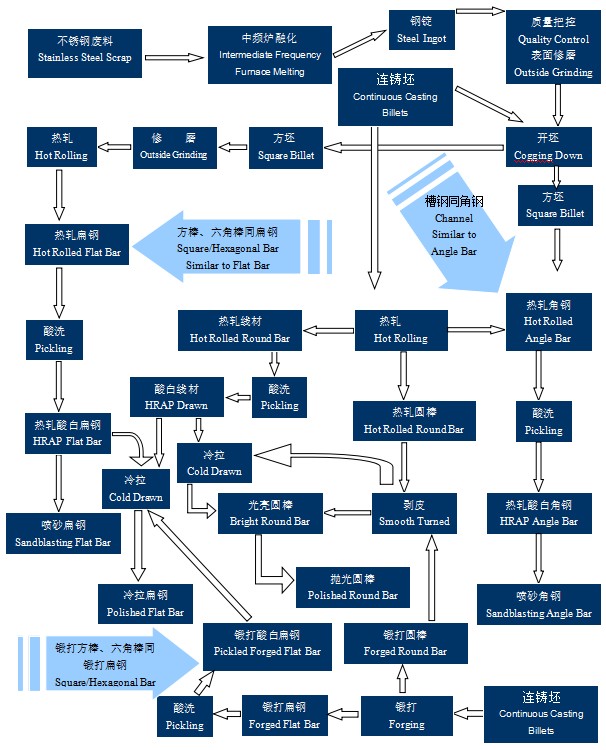

How is the 304/316 stainless steel angle bar were Produced?

Imballaggio & Spedizione

Professional and sturdy packaging protects the stainless steel plates, coils, profiles and rods to the greatest extent, avoiding bumps and scratches during transportation, and it is deeply loved by customers.

PROGRESSO

PROGRESSO