Spacificazione

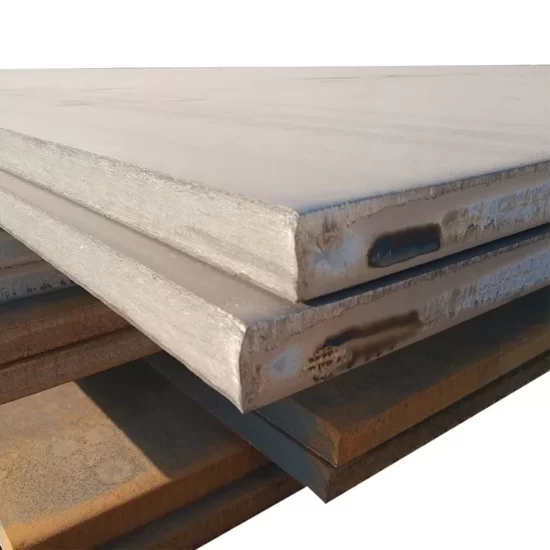

Aisi 1045 L'acciaio è un acciaio a trazione media fornita in una condizione nera a calore o normalizzato. Ha una resistenza alla trazione di 570 – 700 Durezza MPA e Brinell che vanno da 170 E 210.

Aisi 1045 L'acciaio è caratterizzato da una buona saldabilità, Buona macchinabilità, e proprietà ad alta resistenza e impatto in condizioni normalizzate o lamotate a caldo.

Aisi 1045 L'acciaio ha una capacità di maniatura attraverso attraverso solo sezioni intorno 60 di dimensioni mm consigliate come adatte per il temperamento e il mantenimento. Tuttavia, Può essere efficientemente fiamma- o inducenti induttori nella condizione normalizzata o calda per ottenere durezza superficiale nell'intervallo di RC 54 – Rc 60 Sulla base di fattori come la dimensione della sezione, tipo di configurazione, Medium di spegnimento usato ecc..

Aisi 1045 L'acciaio manca di elementi di lega adeguati e quindi non risponde al processo di nitriding.

Composizione chimica

| Elemento | Contenuto |

|---|---|

| Carbonio, C | 0.420 – 0.50 % |

| Ferro, Fe | 98.51 – 98.98 % |

| Manganese, Mn | 0.60 – 0.90 % |

| Fosforo, P | ≤ 0.040 % |

| Zolfo, S | ≤ 0.050 % |

Proprietà fisiche

| Proprietà fisiche | Metrica | Imperiale |

|---|---|---|

| Densità | 7.87 g/cc | 0.284 lb/in3 |

Proprietà meccaniche

| Proprietà meccaniche | Metrica | Imperiale |

|---|---|---|

| Durezza, Brinell | 163 | 163 |

| Durezza, Pulsante (Convertito da durezza di Brinell) | 184 | 184 |

| Durezza, Rockwell b (Convertito da durezza di Brinell) | 84 | 84 |

| Durezza, Vickers (Convertito da durezza di Brinell) | 170 | 170 |

| Resistenza alla trazione, Definitivo | 565 MPa | 81900 psi |

| Resistenza alla trazione, Prodotto | 310 MPa | 45000 psi |

| Allungamento a rottura (In 50 mm) | 16.0 % | 16.0 % |

| Riduzione dell'area | 40.0 % | 40.0 % |

| Modulo di elasticità (Tipico per l'acciaio) | 200 GPa | 29000 ksi |

| Modulo sfuso (Tipico per l'acciaio) | 140 GPa | 20300 ksi |

| Pesce del rapporto (Tipico per l'acciaio) | 0.290 | 0.290 |

| Modulo di taglio (Tipico per l'acciaio) | 80 GPa | 11600 ksi |

Applicazioni

Aisi 1045 è ampiamente utilizzato per tutte le applicazioni industriali che richiedono una maggiore resistenza all'usura e resistenza. Applicazioni tipiche di AISI 1045 sono i seguenti:

| Marcia | Pin | Ram |

| Alberi | Rotoli | Prese |

| Assi | Mandrini | Vermi |

| Bulloni | Ratchets | Ingranaggi leggeri |

| Studi | Alberi a gomito | Asta di guida |

| Asta di collegamento | Barre di torsione | Morsetti idraulici |

Trattamento termico

Aisi 1045 è sottoposto a forgiatura, ricottura, normalizzare, Responsabile dello stress, Processi di tempra e tempra - ognuno dei quali è spiegato in modo più dettagliato di seguito:

- Forgiatura – Riscaldare a 850 ° C. – 1250° C. (1562° f – 2282° f). Tieni premuto fino a quando la temperatura è uniforme. Raffreddare in una fornace.

- Ricottura – Riscaldare a 800 ° C. – 850° C. (1472° f – 1562° f). Tieni premuto fino a quando la temperatura è uniforme. Raffreddare in una fornace.

- Normalizzare – Riscaldare a 870 ° C. – 920° C. (1598° F-1688 ° F.). Tieni premuto fino a quando la temperatura è uniforme. Immergiti per 10 – 15 minuti. Raffreddare in aria fissa.

- Responsabile dello stress – Riscaldare a 550 ° C. – 660° C. (1022° f – 1220° f). Tieni premuto fino a quando la temperatura è uniforme. Immergiti per 1 ora per 25 mm di sezione. Raffreddare in aria fissa.

- Indurimento – Riscaldare a 820 ° C. – 850° C. (1508° f – 1562° f). Tieni premuto fino a quando la temperatura è uniforme. Immergiti per 10 – 15 minuti per 25 mm di sezione. Spegnere in acqua o salamoia.

- Tempra – Ri-riscaldamento a 400 ° C. – 650° C. (752° f – 1202° f) come richiesto. Tieni premuto fino a quando la temperatura è uniforme. Immergiti per 1 ora per 25 mm di sezione. Raffreddare in aria fissa.

Applicazioni

Aisi 1045 è ampiamente utilizzato per tutte le applicazioni industriali che richiedono una maggiore resistenza all'usura e resistenza. Applicazioni tipiche di AISI 1045 sono i seguenti:

| Marcia | Pin | Ram |

| Alberi | Rotoli | Prese |

| Assi | Mandrini | Vermi |

| Bulloni | Ratchets | Ingranaggi leggeri |

| Studi | Alberi a gomito | Asta di guida |

| Asta di collegamento | Barre di torsione | Morsetti idraulici |

PROGRESSO

PROGRESSO